Decoding DC Motor Control: Circuit Diagrams & Beyond

Ever wondered how robots move with such precision or how electric cars accelerate so smoothly? The secret often lies within the intricate workings of a DC motor controller, and at the heart of understanding these controllers are their diagrams. These visual representations, often referred to as DC motor controller schematics or DC motor control circuit diagrams, are the key to unlocking the power and potential of these essential components.

A DC motor control schematic isn't just a collection of lines and symbols; it's a roadmap. It illustrates the flow of electrical current, the interplay of components, and the logic that governs a motor's behavior. From simple on/off switches to complex feedback loops, these diagrams provide a crucial window into the inner workings of a control system. Mastering the art of reading and interpreting these visual blueprints empowers you to design, troubleshoot, and optimize DC motor control systems for a wide range of applications.

The evolution of DC motor control has mirrored advancements in electronics. Early controllers relied on mechanical relays and bulky components. However, the advent of solid-state electronics revolutionized the field, giving rise to smaller, more efficient, and more sophisticated control mechanisms. Modern DC motor controllers utilize integrated circuits, microprocessors, and advanced algorithms to achieve precise control over speed, torque, and position. Understanding this historical context allows us to appreciate the complexity and ingenuity behind contemporary DC motor controller designs.

The importance of DC motor control spans countless industries. From robotics and automation to electric vehicles and consumer electronics, precise motor control is paramount. These control systems enable automated manufacturing processes, power electric wheelchairs and scooters, and drive the intricate movements of robotic arms in surgical procedures. The reliability and efficiency of these systems depend heavily on the underlying design, highlighting the crucial role of a well-designed DC motor control circuit diagram.

Despite the advancements, challenges remain. Issues such as noise interference, thermal management, and component failure can impact the performance and reliability of DC motor control systems. Analyzing DC motor controller wiring diagrams is essential for identifying and resolving these challenges. Effective troubleshooting often hinges on a thorough understanding of the circuit layout, component specifications, and the intended functionality of the system.

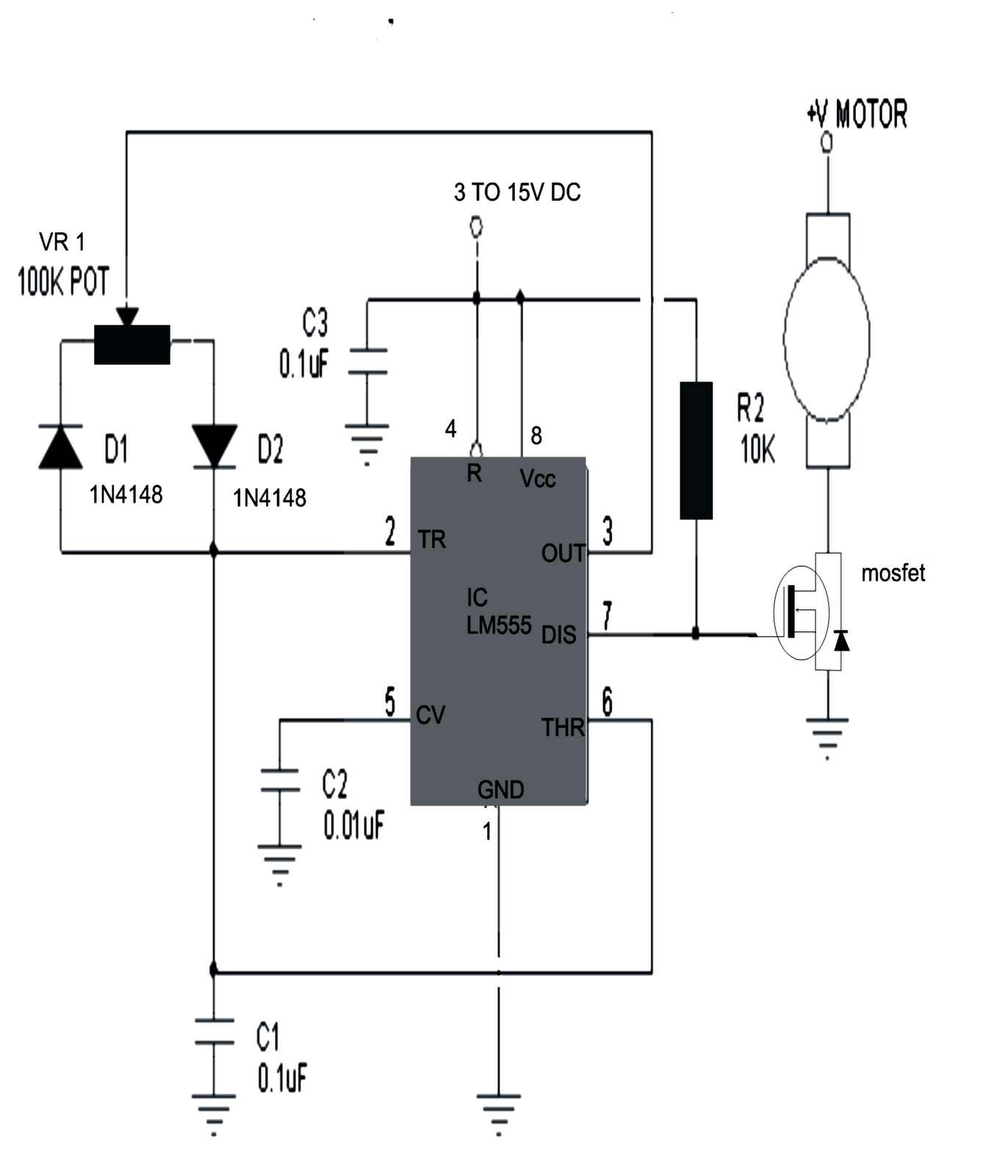

A simple DC motor speed control circuit diagram might involve a potentiometer to vary the voltage supplied to the motor, thereby controlling its speed. A more complex H-bridge DC motor controller circuit diagram uses transistors to control the direction of current flow, allowing for both forward and reverse motor operation. Understanding these different configurations and their associated components is essential for effective control system design.

Benefits of using a well-designed DC motor control circuit include: increased efficiency, leading to lower power consumption; enhanced motor lifespan due to optimized operation; and improved precision and control, enabling finer adjustments of motor speed and position.

Creating an action plan for implementing a DC motor controller starts with defining the application requirements. Next, select the appropriate controller type and components based on these requirements. Finally, develop the circuit diagram, ensuring proper component placement and wiring. Testing and refinement are crucial for optimal performance.

Advantages and Disadvantages of Different DC Motor Controller Types

| Controller Type | Advantages | Disadvantages |

|---|---|---|

| PWM Controller | Efficient speed control, wide range of speed adjustment | Can generate electrical noise |

| H-Bridge Controller | Bidirectional control, efficient braking | More complex circuitry |

Best practices for DC motor controller implementation include using proper grounding techniques, selecting appropriately rated components, considering thermal management, and implementing safety features like overcurrent protection. Real-world examples include using a PWM controller for a fan speed control, an H-bridge controller for a robotic arm, and a PID controller for precise position control in industrial automation.

Challenges in DC motor control include dealing with motor inertia, managing back EMF, and compensating for load variations. Solutions often involve using feedback control loops, incorporating filtering techniques, and implementing adaptive control algorithms.

FAQs: What is a DC motor controller? What are the different types of DC motor controllers? How do I choose the right controller? What is PWM control? How does an H-bridge work? How do I troubleshoot a DC motor controller? What are the safety considerations for DC motor control? How do I read a DC motor controller schematic?

Tips and tricks include using simulation software to test the design before implementation, using datasheets to understand component specifications, and employing proper wiring techniques to minimize noise and interference.

In conclusion, understanding DC motor controller diagrams, whether you call them DC motor controller schematics, DC motor wiring diagrams, or DC motor control circuit diagrams, is essential for harnessing the full potential of these powerful devices. From robotics and automation to electric vehicles and consumer electronics, DC motor controllers play a vital role in countless applications. By mastering the art of interpreting these diagrams, designing effective control systems, and troubleshooting potential issues, we can unlock the precision, efficiency, and versatility that DC motors offer. Explore the resources available, experiment with different control strategies, and delve deeper into the fascinating world of DC motor control. The possibilities are endless, and the future of motion control is in your hands. Dive in and discover the power within these intricate diagrams. The journey towards mastering DC motor control starts with a single line, a single symbol, a single connection. Take the first step and unlock a world of possibilities.

Electric Motor Controller Diagram | Taqueria Autentica

36V48V1500W Brushless Controller Aluminum Alloy Brushless Motor Sine | Taqueria Autentica

36v Brushless Motor Controller Diagram | Taqueria Autentica

dc motor controller diagram | Taqueria Autentica

555 PWM DC motor controller circuit | Taqueria Autentica

Dc Motor Controller Circuit Diagram | Taqueria Autentica

Remote Controlled Motor With Circuit Diagram | Taqueria Autentica

Electric Motor Controller Diagram | Taqueria Autentica

Dc Motor Controller Diagram | Taqueria Autentica

Brushless Dc Motor And Controller | Taqueria Autentica

Brushless Dc Motor Controller Circuit Diagram | Taqueria Autentica

Dc motor speed controller circuit using NE555 | Taqueria Autentica

How To Wire Motor Controls | Taqueria Autentica

12v Dc Motor Controller Diagram Fashionable Design | Taqueria Autentica

Electric Bike Circuit Diagram | Taqueria Autentica